“If you need a machine and don't buy it, then you will ultimately find that you have paid for it and don't have it.” Henry Ford

Get a Quote

“If you need a machine and don't buy it, then you will ultimately find that you have paid for it and don't have it.” Henry Ford

Get a Quote

GMC is a full supplier of sheet metal fabricating machinery including plate rolls, sheet metal brakes, automated folder, shears and HVAC rollformers. GMC should be your first choice to shop for new industrial grade machine tools. GMC manufactures and supplies machine tools for the metal fabrication and metal working industries. GMC offers a wide selection of metal machinery for all your metal cutting, bending, beading, sawing, shearing, forming, and metal punching needs.

Our sheet metal folding machine has become extremely popular amongst the metalworking community. The manufacturing world has demanded more of this model than any other Sheet Metal Folder.

GMC plate rolling (pinch roller) machines roll sheet metal plates in a simple operation, using a German Rexroth hydraulic logic system to clamp your workpiece with ease. GMC heavy duty plate bending machines are made of high grade alloy steel and hardened 50-52 HRC, with hydraulic powered up/down/tilt adjustment.

With our GMC Corner Notchers, you can effortlessly notch corners with precision and accuracy, saving valuable time and effort. Their advanced features and robust construction ensure long-lasting performance, making them a reliable addition to your workshop.

GMC sheet metal bead rollers are meticulously designed and engineered to deliver exceptional performance, precision, and efficiency in metalworking projects. By combining advanced technology with durable construction, we ensure that our bead rollers offer unparalleled durability and reliability.

With a wide range of adjustable settings, GMC machines allow you to create consistent bead formations, tailored to your specific requirements. GMC sheet metal bead rollers are versatile tools that will elevate the quality of your work. Discover the superior craftsmanship and innovative features of GMC Machine Tools!

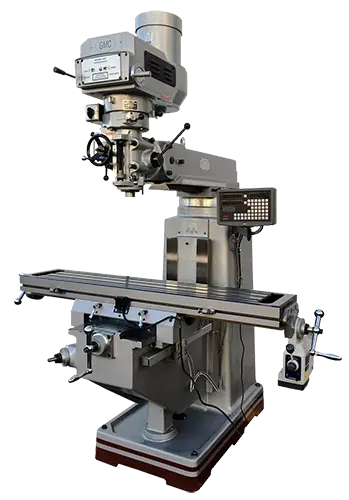

Milling machines are used for removing material from a work piece. Vertical Milling Machines typically work on flat surfaces and can create grooves, threads, slots, chamfers and other types of cuts.

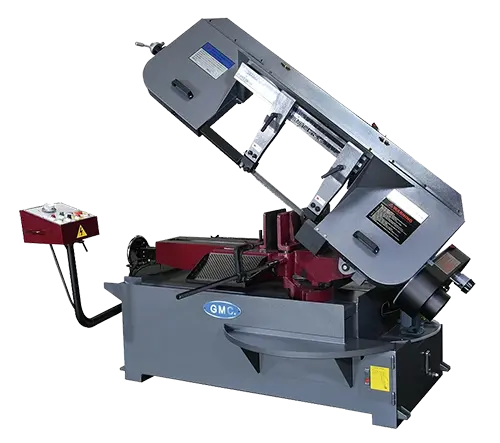

13”x18” capacity, semi-automatic, variable speeds, 3HP. Features a hydraulic vise, power downfeed, and bow automatic return.

* Max. capacity of 9” O.D.

* Variable speed - 66 to 280 fpm

* Gear-driven transmission

* Mitering head swivels up to 60° to the right

* Cast iron mitering head and bow without vibrations

* 8 precision ball bearing blade guides make a clean, high-quality cut

* Patented blade tensioning gauge

GMC metalworking lathes have user friendly features such as including a quick-change gearbox for effortless threading setup. These precision-engineered geared-head lathes come equipped with foot brakes, ensuring smooth metal turning.