“If you need a machine and don't buy it, then you will ultimately find that you have paid for it and don't have it.” Henry Ford

Get a Quote

“If you need a machine and don't buy it, then you will ultimately find that you have paid for it and don't have it.” Henry Ford

Get a Quote

Gripnail offers a variety of fasteners and fastening equipment, each specially designed to affix insulation, duct lining, data plates, wire brackets, and other industrial applications.

The PowerPinner 7100 Welder is a solid state resistance welder designed specifically for welding a resistance weld pin to galvanized sheet metal ductwork. It is lightweight and has extended gun leads which makes it perfect for fastening duct liner to all sizes of duct.

The PowerPinner 7250 Welder is a solid state resistance welder designed specifically for welding a resistance weld pin to galvanized sheet metal ductwork and insulation. With this benchtop welding array, set up shop on any stable surface and fasten insulation with high quality welds.

The PowerPinner 7200 Welder is a solid state resistance welder designed for specifically for welding a resistance weld pin to galvanized sheet metal ductwork. The compact size and hand truck feature allows for easy mobility around the shop. A lightweight pistol grip trigger, ergonomic handle and easy to read controls further simplify the operation.

The new PowerPinner 7005HS boasts the quickest cycle time and most reliable welds available. Functioning without any mechanical reed switches, the 7005HS on-board computer has been turbo-charged for peak performance. The new Programmable Logic Controller produces welding speeds never before seen without sacrificing weld quality.

Contractors who regularly line large fittings and straight duct will find the convenience of the 7105HS speeds their assembly and reduces fabrication costs. The weld head travels a full 60 inches for lining 5-foot wide duct. The head is moved with a multi-position extension arm and glides on specially designed bearings.

Most coil lines are capable of running at 50 feet per minute, but had to slow down to 25 ft/min. when applying welded duct liner fasteners. Gripnail introduced the industry's first 50 ft/min. two decades ago. Ever since we have been centered on continuously making industry leading improvements to the design. The PowerPinner 50 is capable of placing full range of weld pins up to 2" as close as 6" apart to metal as thick as 16 gauge without any extra modifications.

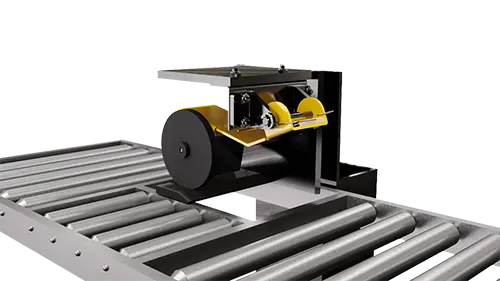

Gripnail's new spacing acquisition module (SAM) provides a way to retrofit coil lines with a new pinner, regardless of the vintage or condition of the coil line controller

SAM is mounted on the frame of the coil line and "reads" the edge of the metal with through-beam fiber optic sensor that detect the notches and an encoder that measures the distance between the notches. These two pieces of information are fed into a PLC which calculates the pin spacing for each duct panel.